What Are Keychains Made of and How to Make them?

It will take amount of time to make even a tiny product. For example, custom made keychains, which are the number one souverir item in the world. No matter the custom made keychains ara made from metal, plastic, acrylic or other material, it will take time, need machines to get them prepared for the keyring. How to create custom made keychains? Why do we like putting them on our car keys? Today, we will learn all about the creation of custom made keycahins.

What are the parts of a Custom Made Keychain?

Before looking into the manufacuring processes of creating custom made keychains, let take a look at the each part of a keychain. A custom made keychain consit of three main parts which include trinket, chain, clasp, ring. The chain is not a must and the clasp may not be in round shape. For example, some custom made keychains has a clasp which has a lobster claw look, and other custom made keychains have a simple ball which fits into a tiny metal piece.

Most custom made keychains are made from plastic or metal. At Morning Craft, we can create custom made keychain in frbric, paper, wood, acrylic, PVC, rubber and more.

How to shape Custom Made Keychains?

The end result of custom made keychains my look different, creating custom made keychain is about shaping the materials and putting pieces of material together. The three methods to shape the custom made keychains trinkets are die cuting, stamping press and injection molding.

Process of die cutting

1, Choosing the material

The choosen materials for custom made keychains is fed into a machine by mechanized rollers. This can be done for plascti, rubber, fabric, wood, paper or sheet metal custom made keychains.

2, Cutting materials with cutting die

A custom cutting die is properly aligned. It comes down onto the material and creates the desired shape. To cut through the material, this cutting die has an attached cutting blade. This step must be done on a flat surface.

3, Taking out extras

If the custom made keychain is made from fabric, paper, rubber or plastic, the excess material have to be trimmed off. As the cutting die is so precise, there is not too much excess material needs to be cleaned up at this stage.

4, Trinket is ready

The trinket part is ready now. Manual cutting die created just one at a time while digital cutting die can produce thousands or even millions with a run of the machine.

5, Attachding the ring

The chains and clasp are produced separatelt, measured and cut to needed size.

6. Your custom made keychain is ready

When the chains and clasp are attached to the custom made keychain, the custom made keychain is ready. The main advantage of die cutting is the versatility in design. At Morning Craft, we can die cut custom made keychains in any shape such as guitars, stars, houses and more.

Process of stamping press

Except for die cutting, custom made keychains can also be made with a stamping press process. Stamping process is similar to medieval practice to shape matel by a hammer and anvil. Today, a hydraulic presss is widely used to shape custom made keychain which are made from strong metal such as iron and stainless.

1, Cutting the shape

The metal material is pressed by a die and a strong machine which is called a punch to achive the desired shape. Normally, it will take around 71 tons of pressure to cut a circle with diameter 10 inches from the metal.

2, Running the machines

The materials are pressed out of the machines continuely to avoid holdups which may break the machine.

3, Moving the blanks

The blank are moved via grippig devices to achive their desired form. At this process, they can be treated as the custom made keychains’ trinket.

5, Reomvee extras

When the trinket is ready, excess material is cut from the meral. The excess material can not be removed by a pair of scirrors, it must be done by heavy tools.

6, Your custom made keychains are ready

The stamping press needs a die. It is ideal for stronger materials compared to paper or plastic. The high-end custom made keychains like graduation gifts are likely created by stamping process method.

Process of injection molding

Injection molding is a manufacturing process which is commonly used to make plastic partsm not only custom made keychains but also water bottles, chairs, toys and other products.

1, Into the hopper

Plastic resin is poured into a funnerl-like contraption which is known as a hopper. Some injection molding machines use giant vacuum which sucks the resin in and get them into the hopper fast.

2, Inject into the mold

The plastic resin runs down the machines into an extruder, in the extruder, the plastic material gets melted down and injected into molds which in custom made keychain shape. Injection molds are usually made from hard metal like aluminum and steel which can withstand high temperature.

3, Removed by robots

A robots remove the custom made keychain trinkets from the assembly line.

4, Attaching the ring

The custom made keychain’s ring and chain are produced separately. They will be attached to the trinkets.

5, Your custom made keychains are done

When the chain and ring are secured, your custom made keychains are ready.

Injection molding is the common method to mass produce plastic custom made keychains. Most promotional custom made keychains aat trade show or funfraisers are likely produced by injection molding process.

How to create custom made keychains?

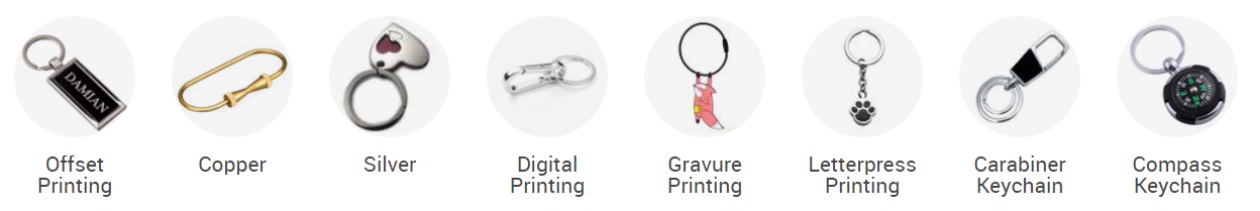

At Morning Craft, our custom made keychain can be created with any message, logo or name. custom made keychains are the great advertising item for many industries. Here ar Morning Craft, we can add to the custom made keychain by the following:

1.Screen printing

Screem printing is a common way to decorate custom made keychains. An emulsion is spread over a screen. The artwork is transferred over to the custom made keychains.

2.Pad printing

Pading printing is ideal for layering colors. Every stamp is covered with a different ink and then applied onto the custom made keychains directly.

3.Digital printing

Ditigal printing can apply the logo or design onto the custom made keychains in full color at no additional charge. Digital printing is colorful and eye-catching.

4.Laser

Laser engraving will not chip or fade. It is more expensive. Laser engraving logo is clean and in polished look.

5.Debossing

custom made keychains with debossed design has a raised and 3D look. Debossing method is suitable for leather or suede custom made keychain.

6.Hot stamping

Hot stamping process is performed bu a hot stamp to create designs on custom made keychains.

custom made keychains are an awesome item to any event. Every custom made keychain tells a story. custom made keychains are also symbols of special memories. custom made keychains are affordable and easy to keep and store. They are the great choice for events, trade show and fundraisers. If you want to create your unique custom made keychains, contact us today.

Next News: How to Create Custom Made Keychains?

.png)

.png)

.png)

.png)